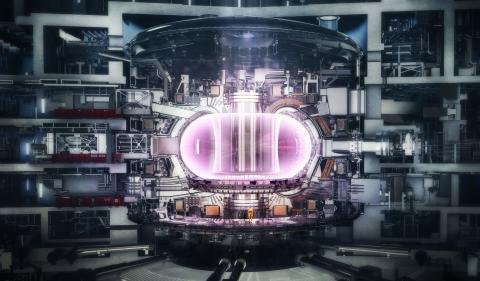

The dream of fusion power depends first and foremost on a self-sustaining fusion reaction, with most of the heating power needed coming from within the reaction itself, rather than from external sources. This is what ITER is all about: trying to create those conditions, in a stable and predictable way, as a starting point towards developing future fusion power stations.

ITER is the world’s largest fusion power experiment and if it can overcome some immense technical challenges, it’s no exaggeration to say that its success will change the world.

Jacobs leads the Momentum joint venture, which is the construction management-as-agent (CMA) contractor at ITER, responsible for coordinating the assembly of more than one million components in the ITER machine. The CMA task began in 2016 but our support to the project, based in Provence, France, goes back decades.

-

44

tonnes – the weight of components connected/disconnected by the Neutral Beam Remote Handling System

-

150 M

degrees Celsius – plasma temperatures wall panels protect the ITER machine from

Jacobs’ contribution to ITER includes the first wall panels which protect the machine from plasma temperatures of up to 150million°C; the test blanket modules, which are an essential part of breeding tritium to fuel the fusion reaction in future reactors; and the remote handling system for maintaining the neutral beams, which heat the reactor’s fuel.

Three heating neutral beam (HNB) injectors heat the plasma by firing a stream of neutral (un-charged) particles into it at a tangent. Exposure to radiation means that the HNB machines will become highly activated, so internal maintenance and repairs will need to be carried out remotely.

We’re leading the European Remote Handling Alliance, a co-operative group of companies responsible for the design, manufacture, installation and commissioning of the Neutral Beam Remote Handling System which will connect/disconnect components weighing up to 40 tonnes (44 tons) and transport them out of the cell to a separate facility.

Design development work, technical specifications and implementation plans for ITER’s integrated plant simulator have also been entrusted to Jacobs and three sub-contractors: the UK Atomic Energy Authority, Fortum and VTT Technical Research Centre of Finland Ltd.

To validate the design and design modifications, plant simulators are being developed for the heating, plasma and cryogenic systems. The integrated plant simulator is vital in understanding the behavior of the full ITER machine because it provides the capability to simulate how these interconnected systems interact. It will also bring an integrated approach to the training of operators and will support the commissioning and operation phases at ITER.