Dune is a smarter way to dry wastewater sludge. This innovative patented technology uses 90% less energy than traditional drying methods and reduces biosolids volume and mass by more than half.

Dune transforms biosolids cake into a dense, soil-like material that’s easier to handle and cheaper to manage through thermal treatment or land application. The benefits include lower transport and disposal costs, reduced emissions and a smaller storage footprint – all while using less power.

As biosolids management faces growing pressures, such as increased disposal costs and land application limitations, Dune provides wastewater utilities with a more effective way to manage wastewater sludge. It benefits all end uses including land application, thermal treatment, landfill and land restoration.

How Dune works

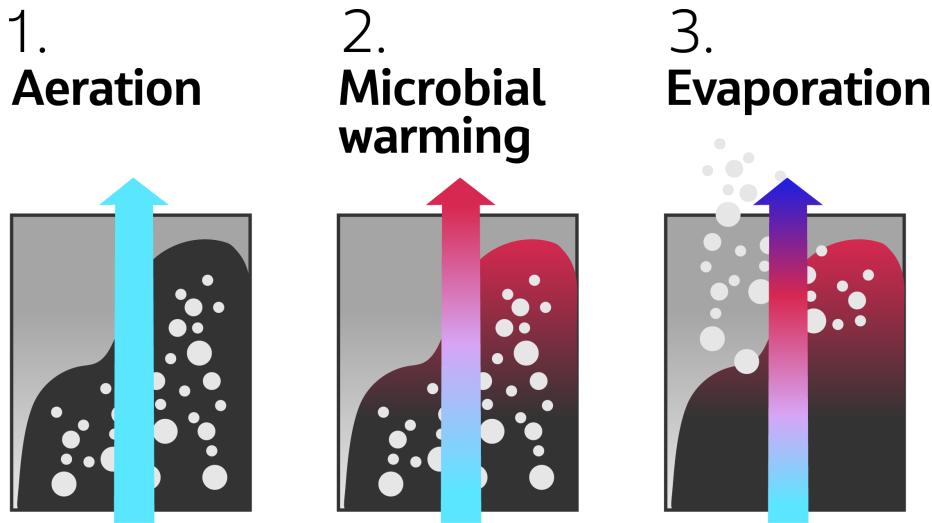

Dune aerates dewatered biosolids, triggering microbiological activity that warms the material. The natural heat boosts the air's moisture-carrying capacity. As the air flows through, it carries away moisture – leaving behind dry, granular solids.

Unlike sludge pelletization, Dune maintains high product density without creating unnecessary void space. It can also be used as pre-treatment before conventional dryers.

Available in multiple configurations and automation levels, Dune can be tailored to fit a site’s needs.

Key Dune benefits

-

Ultra-low energy use

60 kWh per ton of water removed – about 90% less energy than traditional drying methods.

-

Reduced volume and mass

Cuts biosolids cake by more than 50% (based on 30% dry solids input).

-

Versatile end uses

Compatible with a wide range of biosolids reuse and disposal options.

-

Low capital and operating costs

Minimal installation and maintenance expenses.

Dune by the numbers

-

60 %+

water removed from dewatered sludge cake

-

60 %

dry solid output

-

90 %

less energy used than conventional drying

-

4 x

storage capacity because of reduced volume and improved stackability

Get in touch