What’s that sound?

Well, if you’re on a Microsoft Teams call with Samantha O'Farrell, a civil engineer in Jacobs' Jacksonville, Florida office, it just might be a 3D printer.

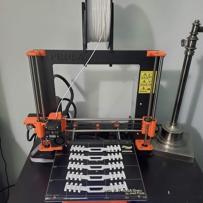

That’s because the machine in her home is churning out approximately five 3D-printed “ear-savers,” an hour. These plastic pieces help alleviate the pressure of a face mask’s elastic bands on the ears – a helpful and thoughtful act of kindness for healthcare workers on the frontlines of the COVID-19 crisis.

Samantha shares, “I don’t own a sewing machine and I never learned how to sew. The best I can do is watch a YouTube video and mend a button, so when requests for people staying at home to sew masks for frontline care workers started, I wanted to help, but knew that making masks was not in my wheelhouse.”

Google must have been putting their social listening skills to practice though because soon, she says, her newsfeed was featuring several instances of teenagers using their 3D printers to create these “ear-savers.”

With a 3D printer at home and plans available online, Samantha got to work — printing more than 65 of these useful “ear-savers” so far and donated the first batch to her local hospital.

Kudos to Samantha for finding a way to help her community, even if her sewing skills weren’t quite up to par.

Jacobs continues exploring ways to leverage our 3D printers in the COVID-19 response. Our team at the Canadian Nuclear Laboratories’ creative use of their 3D printers is aiding in the much-needed personal protective equipment (PPE) need for the medical community.