NASA’s Mars Perseverance rover collecting sample (artist's concept). Photo credit NASA/JPL-Caltech

NASA’s Perseverance rover, the centerpiece of Mars 2020 mission, touched down inside the red planet's Jezero Crater on February 18, kicking off a new era of exploration on Mars. Across multiple NASA Space Centers, contracts and programs, Jacobs partners with NASA to support the rover, delivering innovative technologies that lead to horizon-expanding scientific discoveries.

“Our unparalleled experience with advanced technology systems and our wide-ranging program support capabilities work together to support NASA in their quest to Mars,” says Jacobs Critical Mission Solutions Senior Vice President Steve Arnette. “Our people have provided integrated solutions to help solve the most complex and hazardous challenges of space exploration.”

Jacobs’ contributions supporting NASA’s Mars Perseverance rover:

Delivering innovative technologies for scientific discoveries

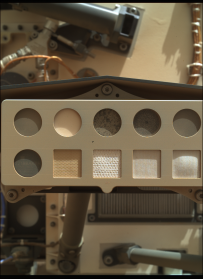

Jacobs and our Johnson Space Center (JSC) customer built a new calibration device for the Jet Propulsion Laboratory-designed rover which will help accomplish a primary objective for Perseverance's mission on Mars, to search for signs of past microbial life and collect rock and soil samples for return to Earth by future spacecraft.

The calibration device will validate whether the science instrument SHERLOC (Scanning Habitable Environments with Raman & Luminescence for Organics & Chemicals) is functioning correctly as it takes in data on the Martian surface to detect signs of possible existence of ancient life.

Mounted on the front of the rover, the calibration device allows researchers to check SHERLOC's analytical instrumentation's accuracy by directing it to scan the baseline materials on the calibration target. If the actual readings are off on those materials, the team can make adjustments to SHERLOC by fine tuning instrument settings to function properly.

In addition to building the calibration device, at NASA Ames Research Center, as the engineering support contractor and wind tunnel operator, Jacobs supported development of parachute technology for Mars landings, arc jet tunnel testing of the spacecraft thermal protection systems, and provided some support to the “MEDLI” (Mars Entry, Descent, and Landing Instrumentation) for Perseverance and previous Mars missions.

Technical leadership for launch management

Our team at NASA Kennedy Space Center (KSC) supported Perseverance and the Agency’s Launch Service Program through offloading, transporting and helping process the rover.

Jacobs supported the offload of the rover at the Launch and Landing Facility and delivered it to the Payload Hazardous Servicing Facility. Jacobs Heavy Equipment and Transportation teams also offloaded, secured and delivered shipments supporting the Mars 2020 mission such as the Adaptive Caching Assembly, the Sterile Flight Model and associated hardware at the Launch and Landing Facility.

-

Jacobs offloads rover at the KSC Launch and Landing Facility.

-

Jacobs offloading Mars rover hardware items.

In addition to offloading, the Jacobs team provided processing services for the spacecraft in the Payload Hazardous Servicing Facility and supported hazardous hypergolic servicing operations to fuel the spacecraft’s propulsion systems ahead of its launch to Mars.

The team also provided Fluids Engineering Support by installing the flex line configuration for BAIR (breathing air) purge that protects the rover Adaptive Caching Assembly – the sensitive caching system that will collect samples on Mars.

Discover additional support from our KSC team in this fact sheet.

Advanced operations and testing for space exploration

At NASA Glenn Research Center, our team on the Test Facilities, Operations, Maintenance, and Engineering (TFOME) contract operates and maintains the 10x10 Supersonic Wind Tunnel and they supported supersonic parachute testing for previous Mars missions. These parachute tests that were completed nearly ten years ago contributed to NASA’s understanding and mastering how to design, pack and deploy parachutes in supersonic environments.

Additionally, wheel development has been a focus of research at Glenn Research Center. Whether you’re on Earth or as far away as Mars, good wheels for space exploration are vital to get your vehicle from one place to another in a Martian or Lunar environment. Jacobs’ technical services supports Glenn’s Simulated Lunar Operations (SLOPE) facility testing wheels within a sandbox to simulate driving conditions for use on the moon or Mars.

For more on how Jacobs is redefining what’s possible, visit our Space Exploration board.