Jacobs. A world where you can.

As climate change threatens water security around the world, more communities are turning to water reuse as a resilient water supply solution and embracing the OneWater principle that all water has value. Jacobs has been supporting clients with water reuse programs for decades, beginning with the first applications of advanced wastewater treatment technologies in the 1960s. We provide our clients with a full range of services, from water reuse feasibility studies to design, construction and operations.

We’ve provided design-build services to the water sector for over 25 years and delivered more than 150 projects. We offer fully integrated design-build and design-build-operate capabilities to tackle the most complex water challenges and work in close collaboration with our clients.

For more than 30 years, Jacobs has been responsible for planning and implementing Lead and Copper Rule-related strategies which protect millions of people in the U.S. and Canada. Our work includes enhanced water quality monitoring strategies, sampling plan development, harvested pipe-scale analysis, lead service line inventories and replacement plans, corrosion control studies and the incorporation of equity and environmental justice considerations into compliance programs.

A curated selection of some of the top-listened to and trending podcast episodes from our popular If/When podcast series.

As a purpose-led company, we know we have a pivotal role to play in addressing the climate emergency. We consider this not only good business, but our duty to channel our technology-enabled expertise and capabilities toward benefitting people and the planet.

We work in partnership, delivering some of the most challenging, diverse and innovative projects and programs globally across multiple sectors. We integrate complex interfaces across planning, procurement and delivery to help unlock better social, environmental and economic outcomes from mega and giga projects.

As our clients navigate the digital transformation and growing cyber risks, we have positioned ourselves at the forefront of this growth, adding digital capabilities, products and tools to serve a growing set of customers.

Sit down with our visionary team of thinkers, dreamers and doers to see what a day in the life is like.

Together with our visionary partner, PA Consulting, we're establishing our position in high end advisory services, creating a springboard to expand in high value offerings beyond the core.

At Jacobs, we're challenging today to reinvent tomorrow by solving the world's most critical problems for thriving cities, resilient environments, mission-critical outcomes, operational advancement, scientific discovery and cutting-edge manufacturing, turning abstract ideas into realities that transform the world for good. With approximately $16 billion in annual revenue and a talent force of more than 60,000, Jacobs provides a full spectrum of professional services including consulting, technical, scientific and project delivery for the government and private sector.

The only certainty about the future is uncertainty. Resilience is an attribute of a smarter planet, and requires planning and adapting ahead of potential threats. We help our clients survive, recover, adapt and thrive.

Jacobs is working to help clients across the United States secure federal funding for projects that make our cities and communities more connected and sustainable. Working hand-in-hand with clients from coast to coast and everywhere in between, Jacobs develops bold, innovative solutions to address the nation’s toughest challenges.

Now more than ever, we appreciate the hard work, sacrifice and dedication of the medical profession in ensuring the health and safety of our communities.

Together, we are stronger. Together, we can transform the future.

Stories that capture our partnerships and innovative impact for a more connected, sustainable world

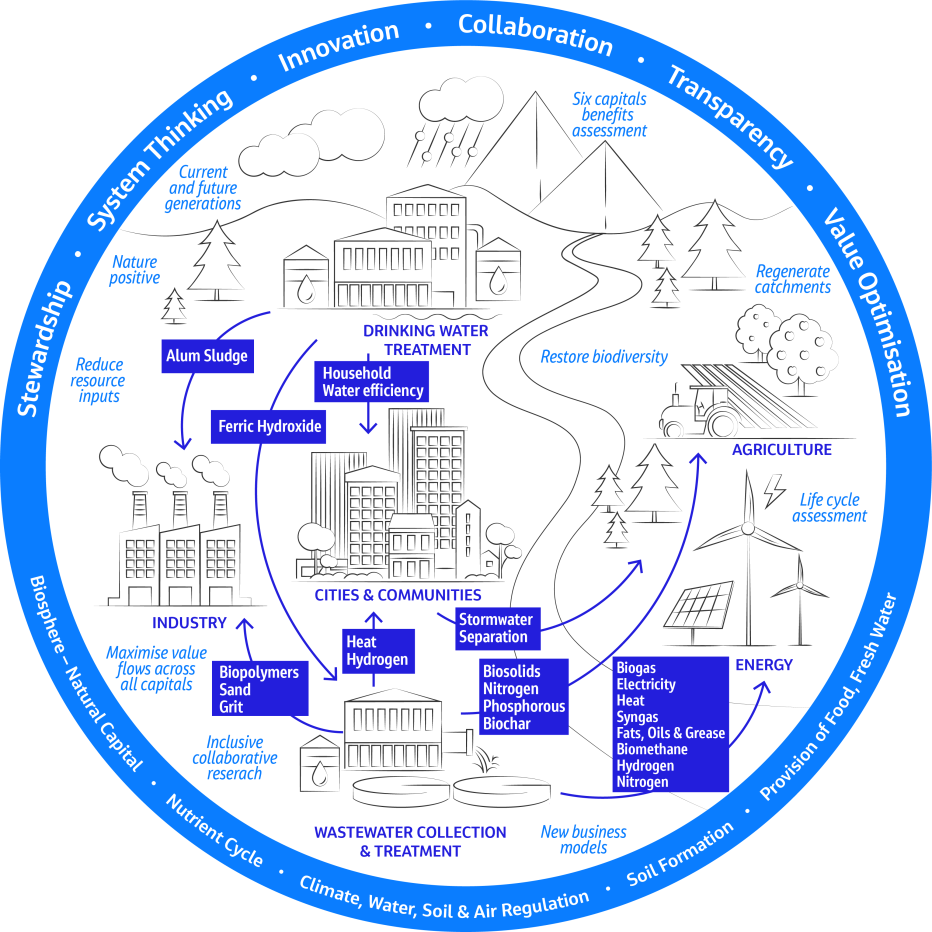

There is increasing recognition and research within the water sector that recovery and reuse of waste materials can contribute to more resilient water systems, promote a circular economy, support net zero emission ambitions and aid positive environmental, economic and social outcomes influenced by water companies. Companies face a dilemma however around where to start and how to develop reuse strategies. In this a context, a best practice roadmap would be valuable.

Industrial symbiosis is the process by which wastes or by‐products of an industry or industrial process become the raw materials for another. It keeps resources in productive use for longer by using wasted resources (including waste, by-products, residues, energy, water, logistics, capacity, expertise, equipment and materials) within or between companies or sectors.

Effective industrial symbiosis:

A circular economy approach enables prosperity and resilience while cutting greenhouse gas emissions, waste and pollution. Download full graphic below.

Ofwat, the Water Services Regulation Authority for England and Wales, established an Innovation Fund to help grow the water sector’s capacity to innovate to enable it to better meet the evolving needs of customers, society and the environment. Through the Fund, Ofwat is hosting a series of innovation competitions that water companies, in partnerships with others, can enter.

Delivered through the Ofwat Innovation Fund, the project has looked at the feasibility of implementing industrial symbiosis within the water sector by applying an innovative digital cloud-based platform resource matching approach. A project team was formed comprising United Utilities as the lead water company representative, International Synergies as the industrial symbiosis subject matter specialists and Jacobs as domain knowledge specialists for circular economy in the water sector to explore a new way of using waste materials from one entity as the raw materials for another. The project team was further supported by water sector input from Dwr Cymru (Welsh Water) and Severn Trent Water, and in particular explored the potential sustainability benefits that could be realized through embedding the concept across capital delivery.

There are a number of major programs that have implemented a similar approach. For instance, the National Industrial Symbiosis Programme (NISP) was implemented in the U.K. in 2003 and has since been replicated in 20 countries at national or regional level. Since 2020, the Dutch water cycle research institute, KWR, is working on implementing industrial symbiosis through the ULTIMATE programme.

This project has provided valuable insight into the potential scale of opportunity of adopting an industrial symbiosis approach in terms of reducing costs and delivering better value within the water sector. The project also highlighted some of the barriers and costs which need to be considered in the pathway for moving from business-as-usual material practices to an industrial symbiosis approach within United Utilities and the water sector more broadly.

A key project outcome revealed the dependency on correct processes, procedures and business culture to fully embed an industrial symbiosis approach to bring about long-lasting, tangible change.

The project team successfully trialed the proposed approach and methodology using 13 months of available data within capital delivery. The trial showcased the potential for embedding industrial symbiosis, including cost and carbon saving estimates for individual live projects. By collaborating with their supply chain partners United Utilities were able to adopt quickly on one project realizing approximately $67,000 (£55,000) financial efficiency.

It further showed the opportunity to yield a financial saving of $17 million (£14million) – equivalent to 1.92% of United Utilities’ overall Asset Management Period 7 (AMP 7) capital delivery budget[1] – and carbon emission savings of 100tCO2e that could contribute towards United Utilities’ net zero reporting and Science Based Targets initiative commitments to reduce carbon emissions.

Of course, a number of barriers were identified to realizing this full potential, for example regulatory, procurement procedures and availability of data. The project reported on each of these, along with potential mitigations that needed to be developed by the water sector and key stakeholders to address them.

United Utilities discussed outputs with Severn Trent Water and Dwr Cymru/Welsh Water, as well as the material-sharing opportunities with the Environment Agency’s Flood and Coastal Erosion Risk Management projects in northwest England. Their feedback was considered in developing an implementation framework for industrial symbiosis across the water sector – both at present and in preparation for AMP8, which could provide a model for replication by other water companies.

Industrial symbiosis offers an exciting opportunity to accelerate towards a truly circular economy. This project has successfully built new capacity and enabled better collaboration across the sector. It also demonstrated a realistic route to applying an industrial symbiosis approach for construction materials on capital delivery programs, showcasing opportunities to expand beyond construction materials to encompass nutrient and mineral resource sharing in water companies. The recommendations outlined a plan to expand industrial symbiosis as we look towards AMP8 and as technology advancements to recover value from bioresources mature.

Pilot projects like this are integral to demonstrating the viability of embedding a symbiotic approach, and can act as a sectoral blueprint to enhance resilience and deliver better value to society and the environment through a more sustainable approach to resource management.