The use of drones has taken equipment imaging and inspections to a higher level for the Jacobs Operations Management and Facilities Services team at National Beef in Liberal, Kansas. Drone technology is allowing the project team to gather more information in less time as they manage wastewater treatment equipment and conveyance infrastructure comprising 15 total miles of distribution lines, nine agricultural pivots and five miles of flood irrigation piping. The irrigation equipment carries treated wastewater from the plant to nearby cropland. The drones also help the team work more efficiently by reducing vehicle travel and saving fuel.

Operator pilots an important innovation

Jacobs Project Manager Troy Ashby decided early-on that he wanted this project to be different. He had a vision of wanting to perform tasks better, more efficiently and safer. Knowing that the Liberal project area was large—3,800 acres with 160 acres of ponds—Troy started thinking. After seeing the imagery that Jacobs drone operator Thomas Benson could produce, Troy knew he’d found his solution and that it would involve a drone. Thomas holds a Bachelor of Science in Unmanned Aircraft Systems from Kansas State University, and he’s an FAA Part 107 Pilot. Thomas developed the initial program, and the team ultimately decided to use drones for thermal imaging. They vetted the idea and implemented it in November 2020. Having purchased the DJI Mavic 2 Enterprise Dual drone, they’re using a state-of-the-art, and budget friendly, machine that boasts a 4K RGB camera and a 160 x 120 FLIR thermal camera.

The team quickly got to work defining goals. They decided on:

- Site surveys for project progression

- Pipeline inspection

- Water surveying

- Pivot inspections

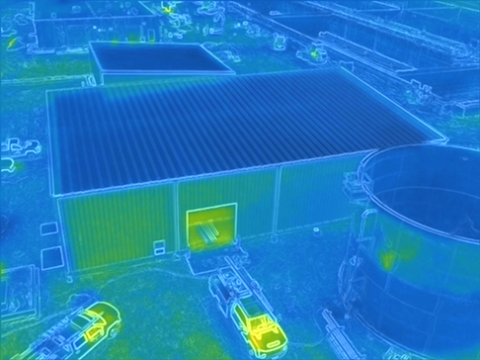

- Roof inspections

- Community assistance

Versatility and safety

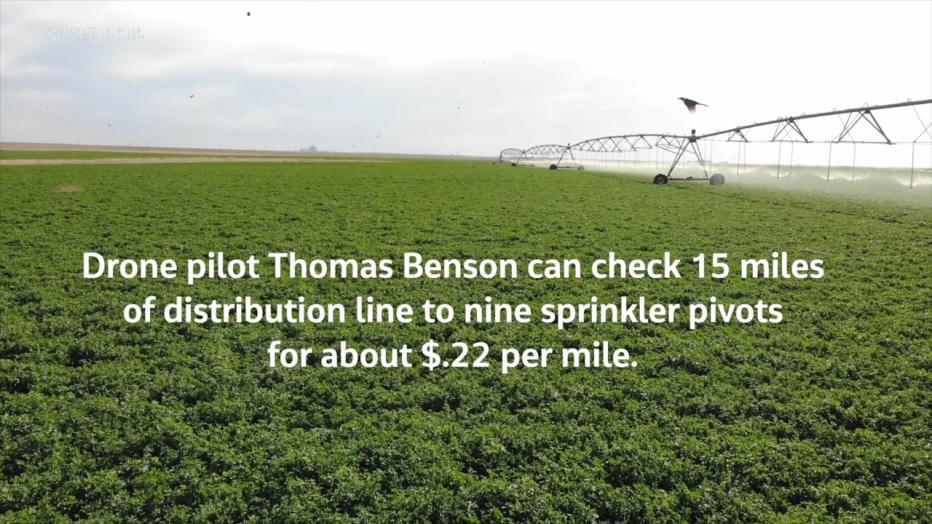

The drone proved useful from the start. Previously when inspecting irrigation lines, an operator would be required to view the line while driving. This method of irrigation line inspection cost approximately $1.86 per mile of pipeline. By using the drone, the team reduced the cost to $0.22 per mile. The drone’s thermographic camera also facilitated inspections of buried lines and equipment.

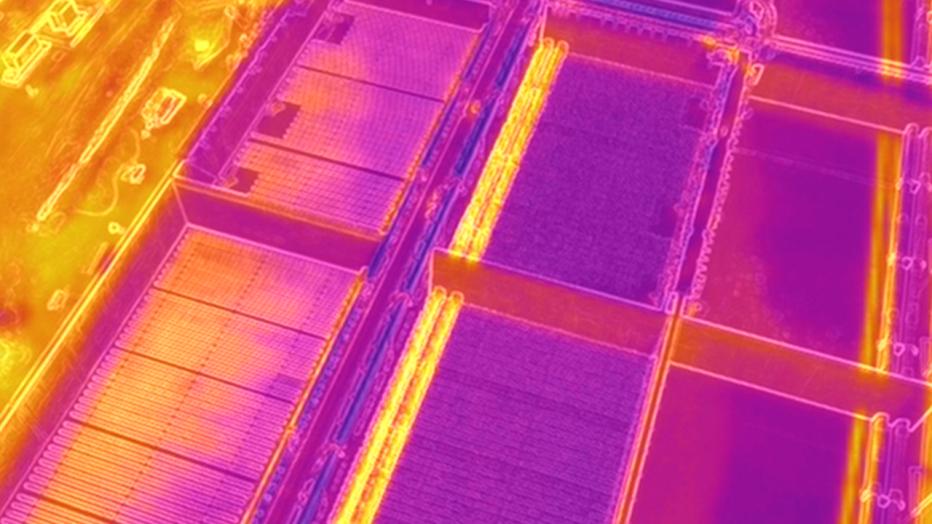

The addition of thermography dramatically increased the quality and quantity of data gathered. Thermographic images aid preventive maintenance. They also enable more detailed assessments of irrigation pivots and help operators inspect structures like roofs and storage silos while avoiding risks and accidents associated with ladder climbing.

The team is considering expanding drone use for more detailed surveys and assessments, mapping and even LiDAR equipment inventory. For now, the technology is saving time and cost, promoting safe and efficient operation, and demonstrating to our client another way Jacobs is doing things right.

-

The drone's thermographic camera helps avoid risky climbing to inspect roofs on the site.

-

The 4K video and still camera can capture images for routine inspections.

-

Drone pilot Thomas Benson leads Liberal's equipment survey and inspection program.

-

The Liberal work site's operational area is more than 3,800 acres of irrigated cropland that accepts treated effluent from wastewater operations.